The New Toroidal – Home on the Range

Most conductivity measurements are done with a contacting, electrode-based sensor. A pair of electrodes are driven by an AC voltage. Ions move between the electrodes and set up a corresponding AC current. Why AC? Because a DC voltage would cause positive ions to pile up on the negative electrode and negative ions on the positive electrode, thus stopping the flow of current.) The contacting conductivity sensor is inexpensive and accurate.

It’s not without drawbacks. A couple stand out:

- In samples with a high concentration of suspended solids or organic solvents, the electrodes become coated and lose their sensitivity.

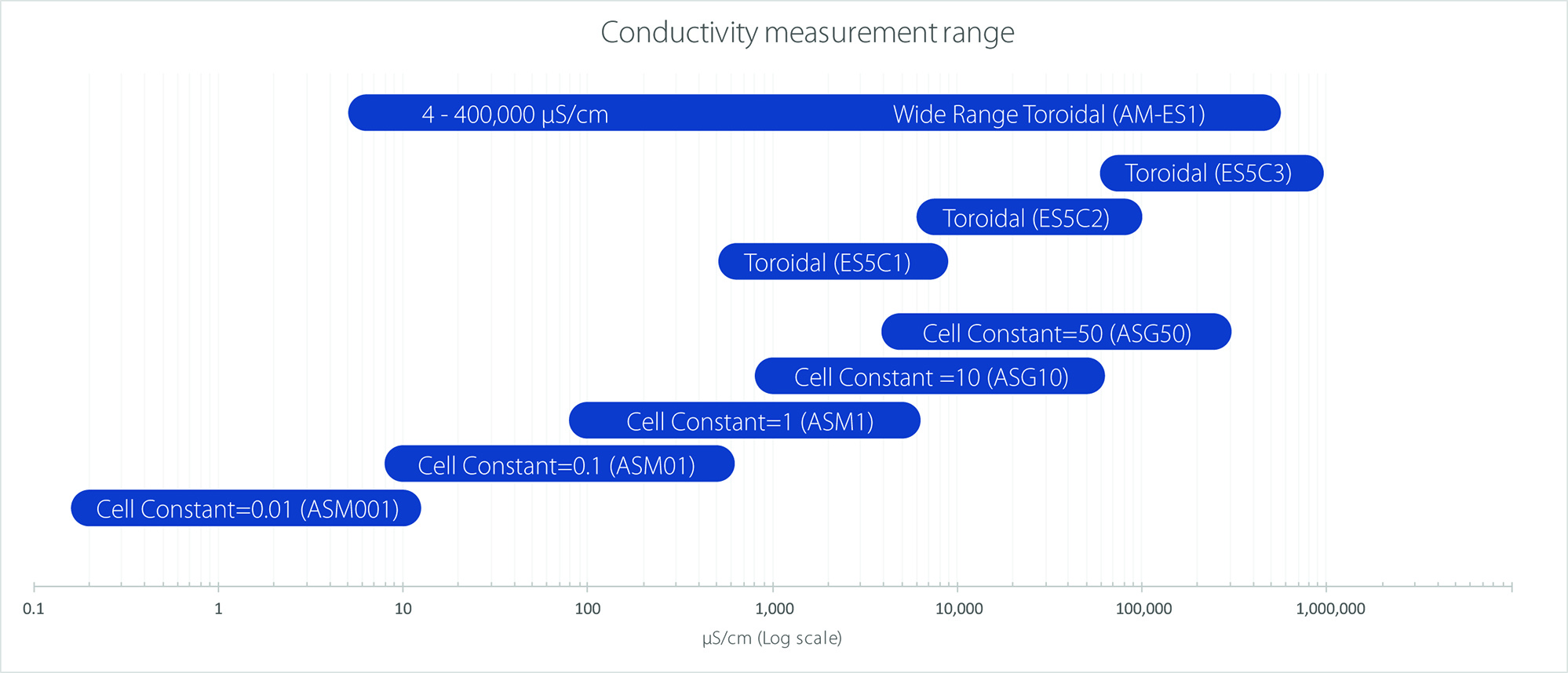

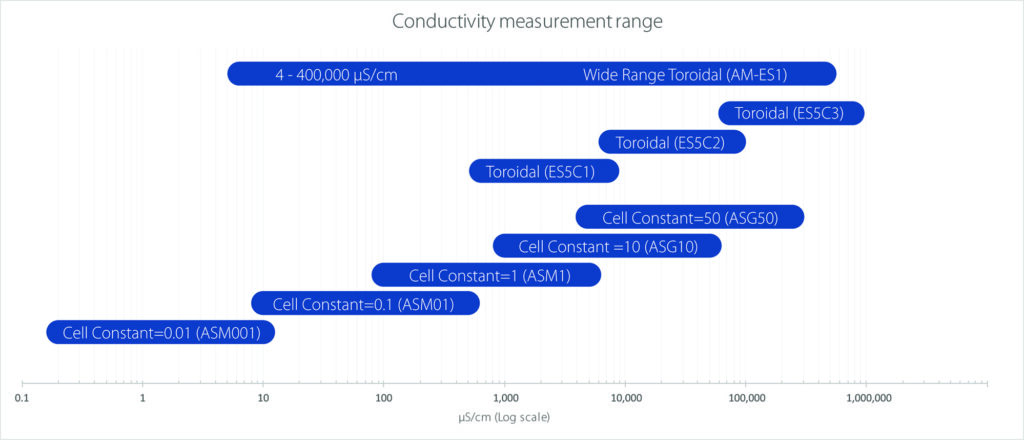

- The range of conductivities in the real world is enormous: from 0.055 to more than 1,000,000 µS/cm, i.e. 10 million to one. A given contacting sensor, by virtue of the geometry of the electrodes, can only cover a range of about 1 to 100. One must pick a particular sensor out of five or more possible ones.

Enter the toroidal probe. This probe works on the entirely different principle of electromagnetic induction: A current through a coil creates a magnetic field, which, in turn, drives a current of ions through the center of the coil and into a second coil that is parallel to the first. The ionic current does the exact opposite in the second coil of the first coil, i.e. it induces a current. The magnitude of the induced current is proportional to the conductivity.

The beauty of this principle of operation is that the coils never need touch the sample. They can be encased in a plastic material and are therefore completely immune from the contents of the sample. This solves the first constraint listed above.

The range of the toroidal probe is dictated by the range of induced current in the receiving coil. In practice at least 100 µS/cm is required to drive a measurable current. On the high end, the maximum current occurs at conductivities of at least 200,000 µS/cm. Most analyzers enable the user to tailor the conductivity range up or down by changing the drive current. Toroidal sensors have a whopping range at least ten times greater than contacting sensors (1000:1) but can’t measure conductivities in the range of pure water.

Until now.

Water Analytics licensed a design initially created at Woods Hole Oceanographic Institute (REVEAL?) that enables a toroidal sensor to measure levels as low as 2 µS/cm—not quite ultrapure (0.055 µS/cm) but sufficient for every industrial application outside of semiconductor manufacture. The high end is the typical 500,000 µS/cm most analyzers reach. The innovative circuit is part of the AM-2251 controller.

The AM-2251 uses a completely different design of the circuitry that drives the toroidal probe. In a nutshell, the circuit reverses the normal operation of the toroidal circuit by driving a feedback current in response to the induced current. By measuring a feedback driving voltage instead of the induced current, the analyzer can measure much lower conductivities.

The illustration below shows the difference. The figure plots the measured conductivity vs. actual conductivity of a series of standards. On the left is the response curve of a conventional toroidal sensor. On the right is that of the new AquaMetrix circuit. Both analyzers cover the higher conductivity range. The difference is the low end.

The key point of the new analyzer is that any toroidal probe will work with the AM-2251 controller. The cell constant of the particular probe determines the actual range. The term “cell constant” is rooted in the geometry of a contacting conductivity sensor with flat electrodes—the ratio of the gap between the electrodes and the electrode’s area. A toroidal sensor does not contain electrodes, so the concept of a cell constant seems inappropriate. However, one can also interpret—and measure—the cell constant simply as the ratio between conductance (µS) and conductivity (µS/cm). The lower the cell constant, the lower the measurement range. Most toroidal probes have a cell constant of 2 or greater in order to measure higher conductivities. The new AquaMetrix ES-2 toroidal probe has a constant of 1.6 so that the AM-2251 can reach all the way down to 4 µS/cm and still reach all the way up to about 400,000 µS/cm. That’s an astonishing 100,000:1 range.

If a user’s process is confined to a range that does not vary more than a factor of ten and it contains a minimum of suspended solids, then a contacting sensor is a more economical choice. If, on the other hand, a process involves more than one range of conductivity or there is a visible amount of suspended solids then a wide range toroidal sensor is a natural fit. Lastly having one sensor that can handle everything except ultra-pure water means having to stock only one sensor.